Interview with Maurizio: our Head of Quarries

Today, we had a chance to interview Maurizio, our Head of Quarries in Tivoli to share his insights on what it is like to work in our Roman Travertine quarries.

Can you give some insight on what is it like to work in a quarry?

I have started my journey at the Poggi company back in 1982 as an intern in the quarry department. At the time, many things were different from today, but one thing that surely did not change over the years: my passion and dedication for roman travertine quarries and natural stone. It is not easy to work as a quarryman: waking up early at 5:30 a.m., you need to be clear headed to avoid multiple risks during the bench extraction phase, and it is necessary to pay attention to what colleagues say and do, as we need each other in every moment during our work.

What has changed in quarry extraction and selection techniques since you started your journey at the Poggi?

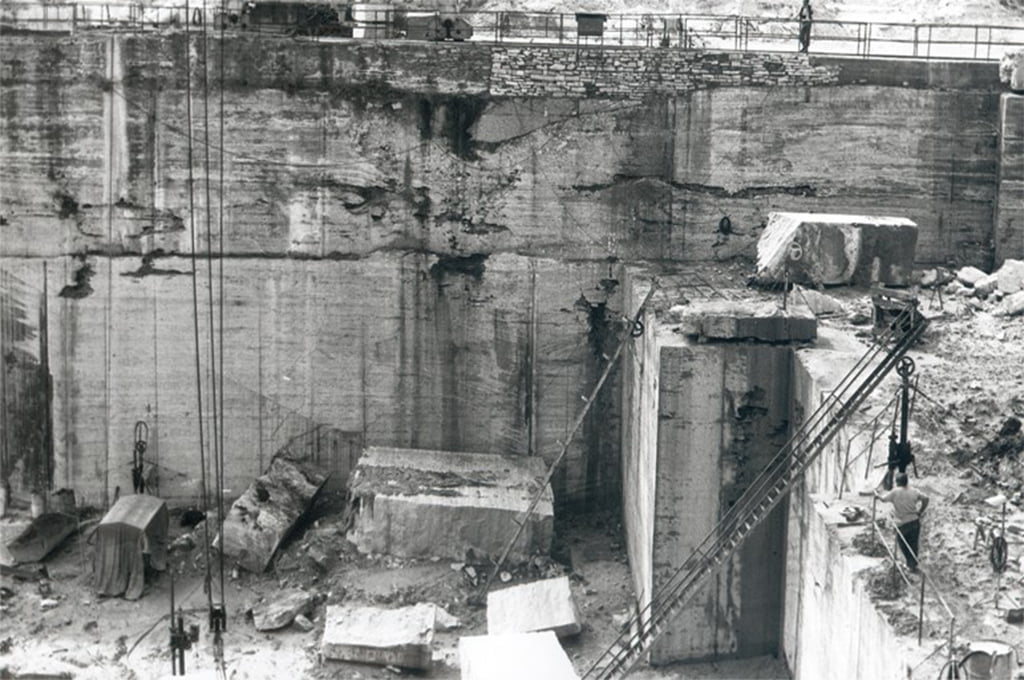

In these 41 years of work, technology has helped us be more efficient and productive and at the same time avoid risks during our job. Before, everything was hand-made and each bench required 80 people who carved and dug the earth just to extract one block. Just to give you an example, before helicoidal sand wires were used to cut the bench accompanied by hand hammering of workers, while today technology has brought us to exclusively use diamond wires for bench cuts making us save invaluable time. Before it was much more of a physically demanding work, but today you need approach the bench with critical thinking and spatial and geometrical awareness to get the most out of our natural stone for the subsequent selection phase.

What is the most difficult part of the job?

Surely selection of natural stone blocks is the most critical part of the job. You need to understand which ones are conform to which subsequent process, if for example a block can be potentially selected for gangsaws and therefore remove its natural imperfections, if suitable for cut to size and objects, or if it is considered production surplus. This you can learn only by doing. An invaluable element that I believe has made me progress in my role as a quarryman is the presence at Poggi of a laboratory for the subsequent transformation of the stone in which we are able to coordinate our efforts and deploy our know-how to produce the best possible result at finished product level.

What advice would you give to someone who would like to work as a quarryman?

Courage and grit are the two main soft skills which every quarryman possesses. In addition, you need to respect natural stone, you need to understand how far you can shape the geometry of a bench and avoid ruptures. You need to be able to calculate risks and make sure everyone works with awareness and in a safe environment. It is important to build a harmonious team, where everyone supports each other, just like a family. I can say that I am very grateful to the Poggi company as they have created a special environment where we as quarryman can thrive in our job and take responsibility of what we do.

Maurizio’s commitment to the Poggi company

Maurizio started working for the Poggi company in 1982. He currently runs the operations of 3 active quarries at the Poggi company and 2 cutting departments. He coordinates the teams and selects the blocks for further processing. He master’s the roman travertine stone benches and has developed unparalleled know-how in natural stone selection.

He has travelled across the globe to study quarrying techniques and improve Poggi’s operations to date, with a view of continious improvement.

Follow Us On Social Media: