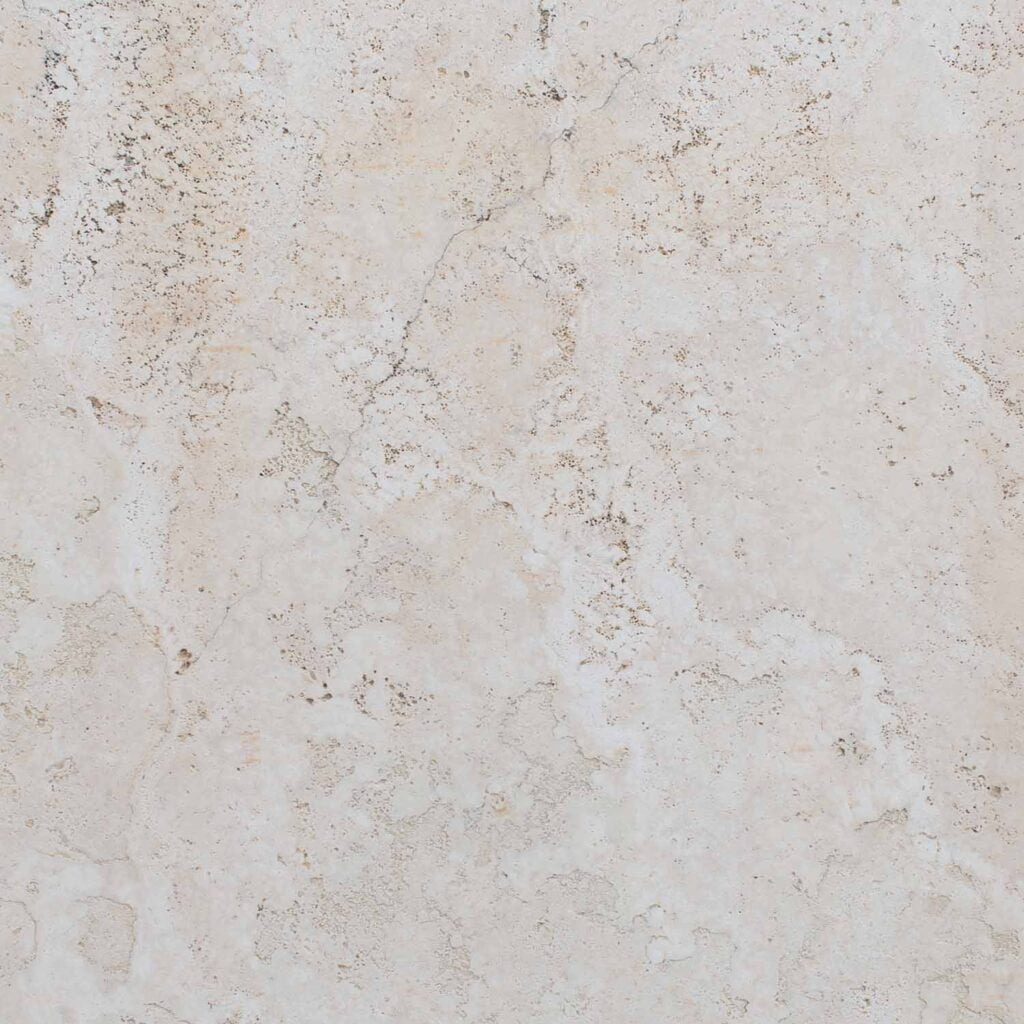

Saw Cut Roman Travertine

Saw cut is the most natural of all natural stone finishes and it is perfect for roman travertine. With over 20 different types of finishes and 50 processings that our company is able to guarantee, saw cut is considered one of the most sober and elegant finishes. It is particularly appreciated by natural stone connoisseurs.

How is the saw cut finish performed?

For this particular finish it is essential to clean the blocks from mud and earth coming from the quarry. This is achieved through cuts of CNC monoblades that can saw the edges of the extracted travertine paying particular attention to details. Without any doubt, the expert’s eye is very important, as their hands are capable of transferring the right balance to each cut.

Contrarily to what one might think, travertine left in the “neutral” state, that is, with an irregular and open-pore surface, is already characterized by a very high resistance, both indoors and outdoors.

The precise and clean diamond wire leaves intact the heart of roman travertine, also honoring its intrinsic aesthetic qualities, capable of giving value, enriching and furnishing any environment, even the most minimalist. As no additional polishing or processing is applied next, the surface is rough to the touch and yet flat, also, the wire doesn’t leave any marks on the stone.

Saw cut finish properties

The saw cut roman travertine finish allows to leave the appearance of the raw material almost unaltered with all its original and natural characteristics. The streaks, the typical colors of travertine, the natural porosity of this stone and therefore its “anti-slip” feature are preserved. That is why roman travertine is a natural material sought after for outdoor projects, especially for swimming pool flooring.

However, tiles in saw cut finish are frequently seen in interior cladding and flooring too. All this is thanks to the fact that roman travertine is indeed resistant and easy to clean. Interior designers and architects appreciate the elegant effect they produce on the environment.

The choice of this finish is perhaps the greatest demonstration of love for our core material, the natural stone from Tivoli, its millenary history and the representation of the heart of Rome.

Follow Us On Social Media: