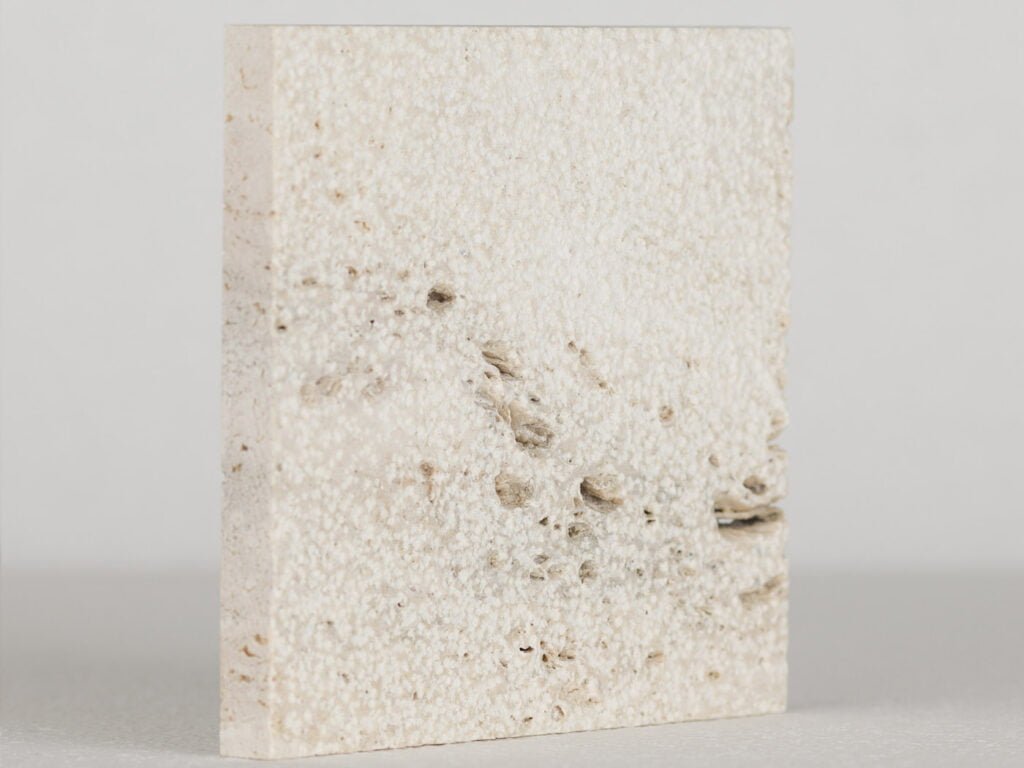

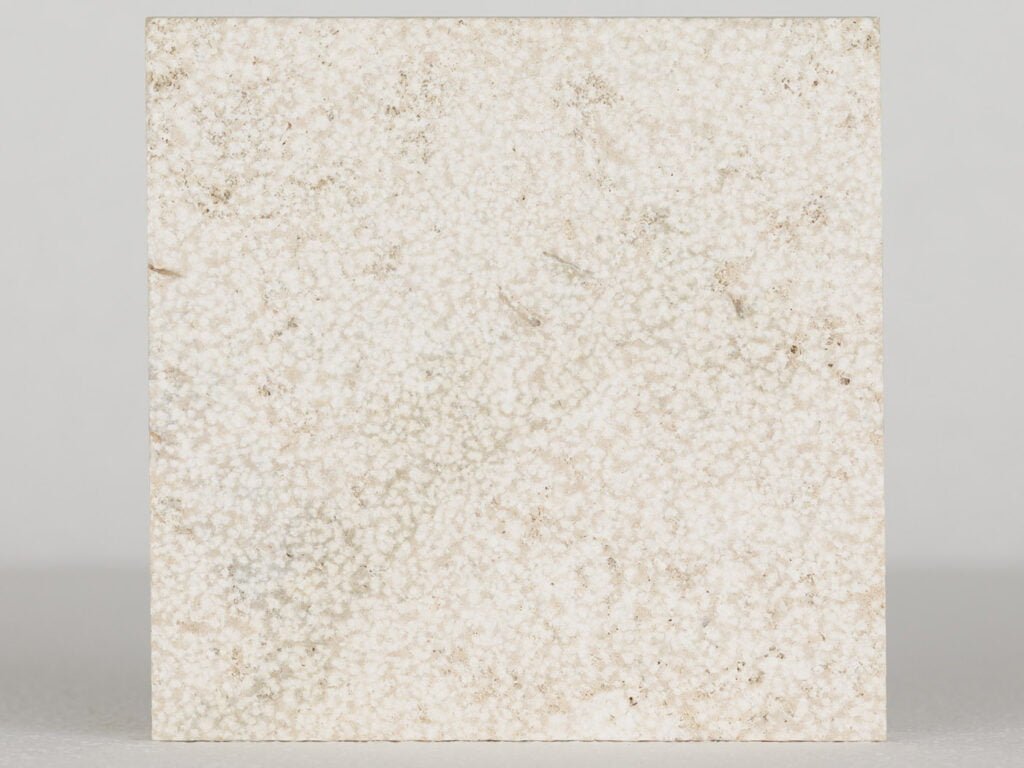

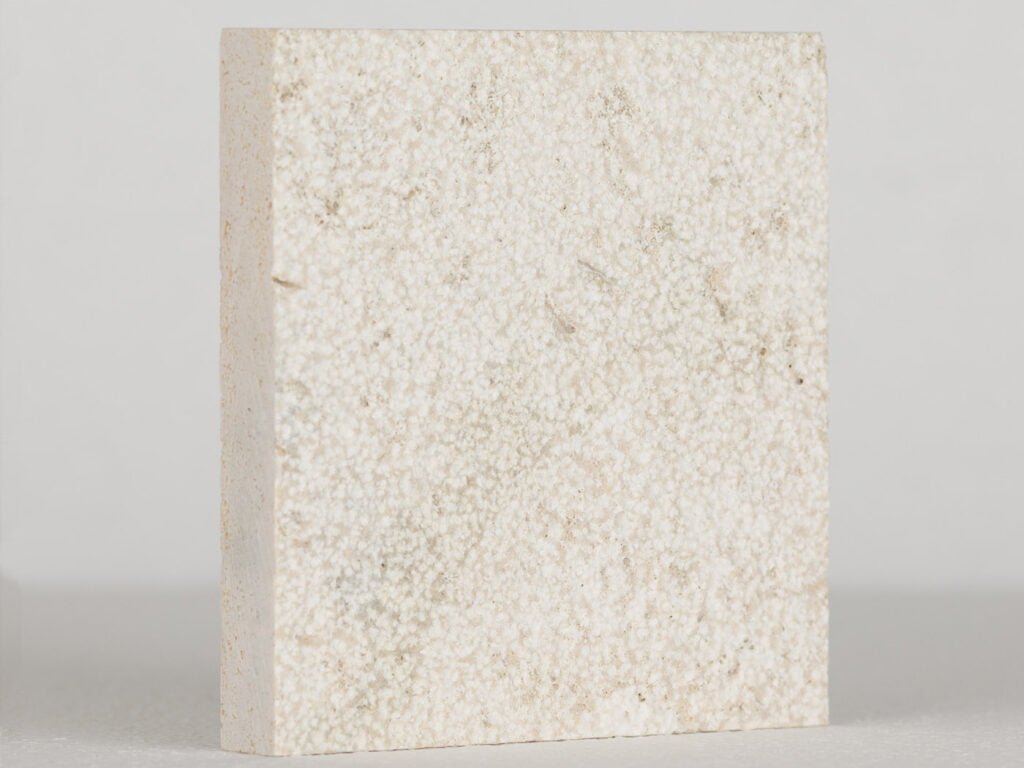

Bush Hammered Roman Travertine

In the wake of the very long tradition of working with roman travertine, the bush hammered finish is together one of the most requested and one of the oldest stone finishings. There are traces of this stone processing even on ancient artifacts dating back to the Classical period. However, its official identification dates back to the Middle Ages. The name comes from the tool that was used to obtain this particular effect, the Bush Hammer. This utensil is characterized by a steel head with conical or pyramidal undulations. The final result on the surface of roman travertine consists of a particular “rippled” effect.

How is bush hammering performed today?

Following modern technological innovations, the ancient hand Bush Hammer tool was replaced by specialized machinery. Today, this particular stone finish can be applied on large productions, as a result of developed know-how. The final outcome for this mechanical finish maintains the handmade effect, improving the stone homogeneity. In addition, it ensures a whitening effect on roman travertine. The contribution of high-tech machinery serves to meet the needs of contractors and architects for high-end large scale projects. However, this has no impact on the original “weathered” effect, which is indeed preserved.

Why is the bush hammered finish used?

Different factors lead to the development of this particular finish, some purely aesthetic, others very practical. On the one hand, Bush-hammered roman travertine has the aesthetic advantage of presenting a slightly “corrugated” surface. This helps resemble the natural stone saw cut surface, with a slight chiaroscuro effect on travertine. On the other hand, this finish is well renowned for resisting over time and for making the stone naturally non-slip. With these two practical advantages combined, it is no secret that this finish is often used on outdoor flooring, swimming pools and stairs.

Follow Us On Social Media: