Travertine Thickness

How thick should travertine be? Our article guidelines will provide you with suitable suggestions on the ideal travertine thickness while getting the most out of the quality of this natural stone.

Roman travertine is world-famous for its refinement and timeless beauty. It is a natural stone capable of lighting up and radiating warmth in any setting. But there is more: this is an extremely resistant material. Its toughness and compactness allows us to transform it without running the risk of breaking it.

The secret is the quality of Travertine, experience and know-how

Travertine quarries can be found in different parts of the world. But only roman travertine can really count on specific hydrogeological properties. This is what makes the stone the most resistant, compact and easy to work among all other kinds of travertine. The reason lies on the basin’s depth, which has a great influence over the toughness and weight of this natural stone. The extraction of roman travertine at the Poggi quarries takes place at a depth of tens of meters ensuring a thick texture and material compactness. This, in turn, allows us to cut roman travertine in both vein cut and cross cut.

Not all travertines are suitable for both cross cut and vein cut processing. Travertines that originate from plane quarries are recommended to be processed only in cross cut. This is beacause they may lack the technical characteristics of resistance and durability in the long term. In addition, thickness plays a crucial role according to the way in which the material is cut, processed and subsequently installed. For example if a customer requires a bush hammered finish on vein cut travertine, the minimum recommended thickness is 2cm. In fact, at lower thicknesses, the pressure that machines apply on stone slabs will be greater than their flexural resistance. Subsequently the risk of damage or breakage during processing or even during installation might occur. It is extremely important to ensure that the material will be durable and will meet installation needs of customers.

In order to ensure the maximum efficiency of our production, our blocks undergo a stringent quality check while our work is carried out in complete safety and sustainability. This is proven by our ISO 9001, ISO 18001, ISO 14001 certifications.

Tiles manufacturing process: from extraction to gangsaw blades

We are committed to offering cut-to-size of the best quality. The process that leads to produce qualitative final products requires experience and specialized capabilities. It all starts with the extraction of travertine benches: the blocks are cut off of the basin following their natural shape and geometry with the help of a diamond wire.

Each block is then cleaned and inspected so that only the best looking ones, according to color, structure, and dimension, are selected and brought to the next stage: the squaring. This stage is meant to cut out any sort of defect and clean the block from dust and soil.

After the blocks are refined they are cut into slabs. All the machinery we employ is state-of-the-art and extremely reliable equipment, which allows us to cut the slabs into different thicknesses. Our gangsaw blades carry out standard cuts at 1.3 cm, 1.5 cm, 2 cm, 3 cm, 4 cm, and 5 cm, but we also supply customized cuts (for example, at 1cm, 6cm, 8cm and so on).

Once the slabs are processed as per customer’s needs, they are finally ready to be brought to our laboratories. Through the artistry of our stonemasons, they are shaped as tiles or pavers in the required dimensions.

What Travertine thickness is best for me?

Since every project is unique many are the factors that influence the choice of the right thickness for travertine cut-to-size. We aim at meeting the needs of our customers and the peculiarities of the project, and we are always ready to offer our support with technical and consulting services from the early stages of the design. However, as a general rule, the wider the surface of the tile, the thicker the travertine should be.

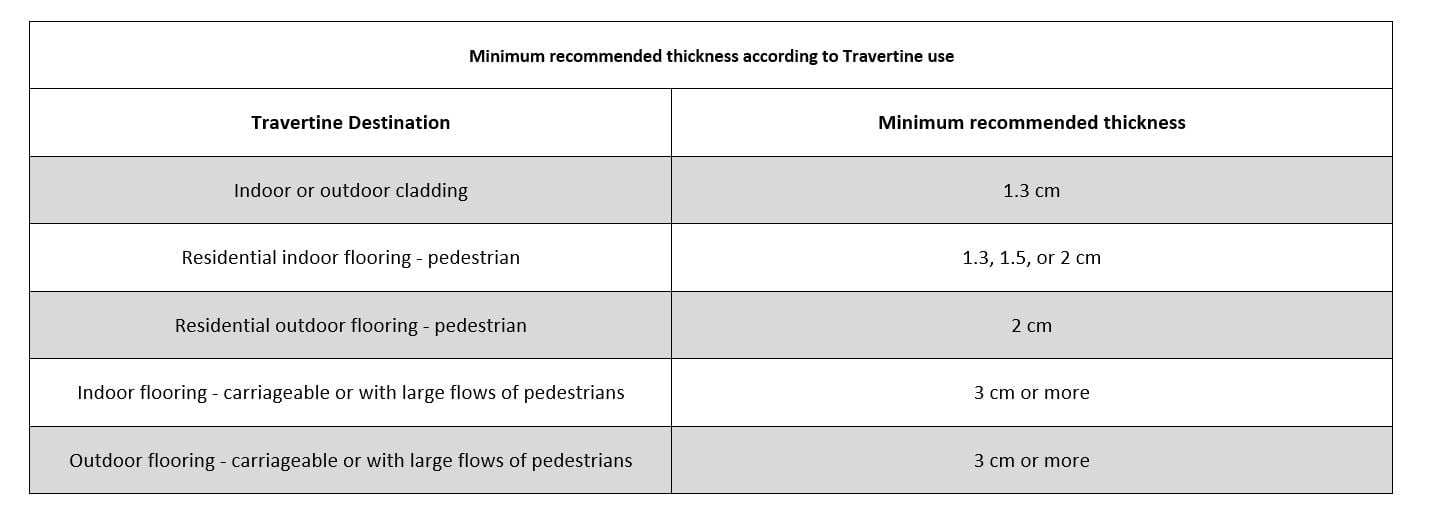

Here is an overview of suggested thicknesses according to the dimension and the use of Travertine cut to size:

We advise our customers to contact us for technical and consulting services. This way we will be able to assist in your choice and provide the best thickness according to your project.

Follow Us On Social Media: